The Integration That Will Revolutionise Your Manufacturing Process

Reach your business potential by taking your manufacturing to the next level. With the use of the powerful EdgeCTP and FreeAgent integration, you can simplify your physical goods-making process to manage your workflows like an industry front-runner.

For a Smarter Business. Don’t Change. Innovate.

EdgeCTP’s step-by-step workflows allow you to take control of your production and innovate your manufacturing process.

FreeAgent’s seamless connection with EdgeCTP converts your sales estimates into work orders and provides a Bill of Materials (BoM) for each order to ensure you have the exact quantity of stock necessary.

With this comprehensive integration, you can guarantee that you’ll have a smooth-running manufacturing inventory system to match your business’ needs.

Source & Demand

EdgeCTP makes it quick and easy to source materials by batch, serial, and expiry level, so you can get the most out of your stock.

With a one-click demand analysis feature, you’ll know exactly how much you’ll need to make your product – so, no more guessing.

Spot shortages before they become a problem. Generate purchase orders to stay ahead of demand.

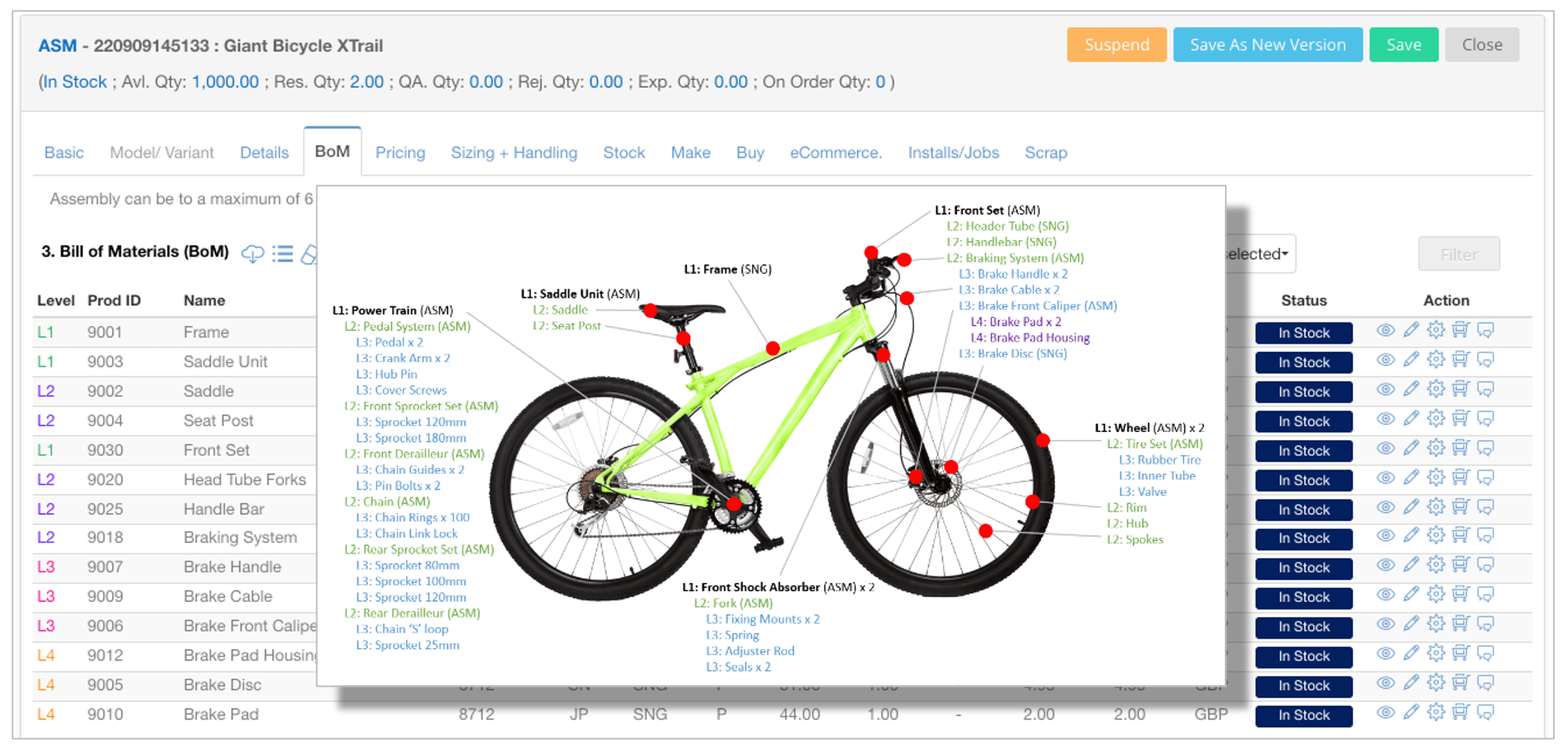

Bill of Materials (BoM)

EdgeCTP’s Bill of Materials (BoM) feature offers a fast and effective solution for identifying the materials you need to create your products, allowing you to keep up with demand.

With EdgeCTP, you can undertake a country of origin analysis to identify where each material used in your product is from. This way, you can clear customs faster and avoid unexpected charges related to incorrectly declared material origins.

Batch Tracking

Stay up to date on the progress of your sales order with batch tracking.

Batch tracking groups similar items and helps you improve the accuracy of your inventory and track specific products even after they are sold, allowing you to implement a smooth recall process that will suit your needs.

This helps you spot errors during and after the manufacturing process and deal with them as fast as possible so that you can kick back knowing your manufacturing is under control.